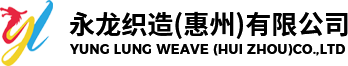

Post-dyed webbing

[01] original white yarn dyed yarn

Put the white yarn into the dyeing vat for dyeing, and it will become "colored yarn" after completion.

[02] color yarn weaving finished products

The "colored yarn" is made into a colored yarn head (warp yarn) by the process of warping and drawing. The finished plate is put on the loom, and the warp and weft yarns are interlaced to make "finished webbing". The finished product is sorted and counted (length) by the whole belt and slitting process.

[03] finished product ironing

Put the "finished webbing" in the dyeing and finishing machine, and iron the "finished webbing" with steam at high temperature to make it flat.

[04] tape packaging and quality inspection

"Finished Ribbon" is ironed and straightened by manual belt stealing, packaging and quality inspection using a tape machine.

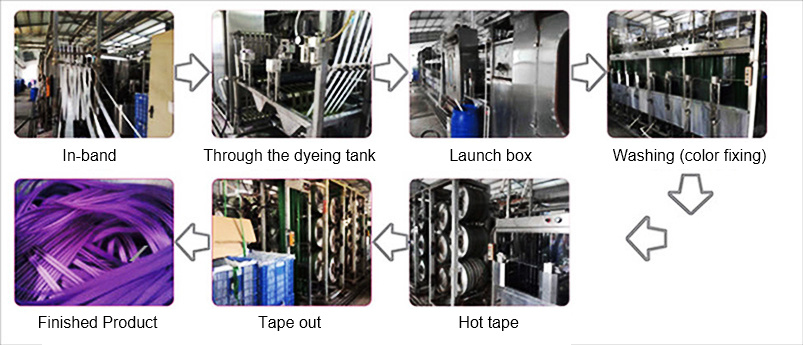

[05] Laboratory testing

Sampling of "finished webbing" shall be carried out according to the inspection standards required by customers.

[06] Shipment

After passing the inspection of "finished ribbon", enter the warehouse to be shipped and wait for shipment.

Subscribe and get news

Contact Information

Yonglong Weaving (Huizhou) Co., Ltd.

Address: Changbu Village, Xinwei Town, Huiyang District, Huizhou City, Guangdong Province

Telephone:13829905177Chen Sheng Phone:13631502993Miss Liu

Fax: 0752-3521132

E-mail:info1@yunglung.com

Enterprise website:www.yunglung.com

Focus on us

WeChat Public Number

Copyright©2024 Yonglong Weaving (Huizhou) Co., Ltd.